Archive for the ‘Uncategorized’ Category

I came across this sculpture while doing some research on mechanical sculptures. The video is a bit long, but the creations look like a good way to use a bunch of surplus motors. . . They make a noise that sounds like falling rain or a racquetball court – or – something.

>>>> Click here to see the works made by the artist called Zimoun

Freightliner website shouts:

Think it can’t be done?

THINK AGAIN.

Freightliner Trucks drove a Cascadia 113 day cab tractor powered by CNG from LA to DC…

>>> Click here to see a video about this CNG-fueled cross country trip

It’s been a long time since I posted an update on the Factory Five Racing Coupe. Here is an update in pictures and captions . . .

-

-

Type 65 Coupe complete kit brake reservoir bracket location

-

-

Polished stainless steel brake reservoir can, Type 65 Coupe, Complete Kit

-

-

I added a plastic grommet from the hardware store electrical section to prevent chafing the brake fluid hose.

-

-

I followed the hose layout as shown in the current Roadster build manual.

-

-

I used a big socket (35mm, I think) in a bench vise to bend my brake lines. Nothing fancy.

-

-

Brake lines are bent into rough shape, then taped in place along its route. Final bending is done on the chassis by hand.

-

-

Brake line held in place with tape, More adjustments are done by hand. Notice the way the excess lines are curved – this allows flexing in two planes – up and down and left and right. This is a 40-inch, pre-flared line I bought at a local car parts store. The supplied 60-inch line was way too long.

-

-

I start my brake line layout by marking the center of the span. This is the large rectangular tube going across the rear. The white wire (number 12 solid copper house wire) is used to make an extremely rough approximation of how the line will run.

-

-

Here you can see the white wire mock-up next to the steel brake line. The roughly Ohmega shape is centered above the IRS pumpkin.

-

-

I decided to run the rear brake line on the inside of the firewall. It will look cleaner in the engine bay and will help keep the line cooler.

-

-

I got lucky. I used a 60-inch line from the rear master cylinder, down the inside of the firewall, and ended up under the driver seat area. A second 60-inch line goes from the union to the rear brake tee. No custom length needed.

-

-

Here’s how the line goes up the support next to the lower rear sway arm. It will be slightly bent away from the chassis and held in place with the insulated line clips to prevent chafing.

-

-

Going up to meet the rear brake flex line, driver’s side.

-

-

A peek into the pedal box – I am still not quite sure how this is going to work. The sheet metal on the right is going to be covered by the Coupe body, so this will be riveted – or screwed – into place. The open side on the left is going to have a one-piece cover. Will this provide enough access for brake balance and clutch cable adjustments?

-

-

Inside the pedal box, showing the front brake line going to the master cylinder. Not as pretty as some others I have seen, but I can always re-do this later, right?

-

-

Here is a view of the rear brake line going to the second master cylinder. I drilled out one rivet fastening the sheet aluminum to the firewall and replaced it with an 8-32 stainless steel screw. It holds the line clip as well as the firewall panel.

-

-

Next on the to-do list: Wiring

-

-

Next on the to-do list: Fuel tank.

It has been very hot in the garage over the last several weeks, temperatures in the garage were about 95 degrees F (35 degrees C) – I finally did a functional test of my portable air conditioner. This is not a new idea, I saw this several years ago on some maker/hacker site, and there is a commercial version of something very similar to this sold at recreational vehicle and camping stores.

Basically, it is an ice chest filled with ice water, some 12VDC fans, an automotive heater core, a marine bilge pump and some hose. Ice water circulates through the heater core while one fan blows air into the cooler and another fan blows air out of the cooler.

I need to cut a notch in the cooler to make way for a bracket, but it is otherwise complete.

This thing made me think about making a water-cooled vest, using a smaller pump and my back-mounted water carrier – it would be perfect for events like Burning Man and ROCstock!

-

-

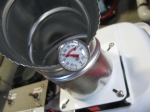

The KH6WZ Air Cooler under its first test. Ambient temperature was 95 degrees. The cover does not fully close because of some mounting bracket interference. This will be corrected and more tests will be run.

-

-

Fan only running, with ice. A drop of almost 10 degrees.

-

-

With fan and pump running, an additional 3 to 4 degree reduction. I think the effectiveness will improve if the container is fully sealed and more ice is added.

Freightliner Cascadia 113 with Cummins Westport ISX12 G CNG engine and Allison 4000 automatic transmission.

Photo from: TruckingInfo.com

http://www.truckinginfo.com/channel/products/news/story/2013/08/freightliner-adds-sleepers-aero-long-range-tanks-to-ng-lineup.aspx

Click here to see >>> A nice video tour of a new vehicle fueled by Agility Fuel Systems

Some friends at the office launched a helium balloon last weekend (Sunday 25 August). We talked about tracking the balloon and of course, I have several ham radio “tracker boxes” that interface a GPS unit to ham radio and then the Internet. Making something small and lightweight could be something that can be part of the payload for a high altitude balloon.

Interestingly, I had a project in my mind ever since I started my various beacon projects many years ago: It is a 21st century message in a bottle – build a disposable, waterproof, floating APRS beacon that I can throw overboard and into the ocean. Then the world can track this thing as it floats around. It will have some instructions on what to do with it if it is found. And, if the finder is or knows a ham radio operator, I will ask that they throw it back into the ocean so it can be found and tracked again.

Here is a picture of one of the main ingredients I will be using:

An old but working 2 meter HT can be put to good use as the RF portion of an APRS beacon.

The plastic case, battery pack and rubber duckie antenna will be discarded to reduce weight. LED indicator lights will be disconnected to reduce current consumption. Other parts or functions will be deleted to conserve space, weight and power consumption.

The APRS modem will be a TinyTrak unit, as with my other APRS projects.

I may build two of these, one for balloon flights and one for message in a bottle use.