Archive for January 2013

I received some sad news today from EDN. Eric Lidow, one of the last true electronics pioneers – passed away on January 18. I worked for his company, International Rectifier, from 1998 to 2006, but used IR components in my electronic projects since I was a kid in elementary school. And when I was in the eighth grade, I won the Science Fair, Physical Science Category, with my “Photo Phone” – which used an International Rectifier solar cell in the receiver.

One day at the office, I received a plain envelope with just my name on it. Inside was a hand-written note from Mr. Lidow. He thanked me for “not presenting our products with too much hype.” I still have that note in my files, and will always remember his advice.

Visit the International Rectifier website, a lot of my content is still present in the archives. . .

International Rectifier

The EDN story

The front IFS is still not right, and the responses from the forums and the directions are confirmed by Jason at Factory Five Racing. Now the difficult task involves more un-building and hoping parts are not damaged. The ball joint on the passenger side needs to be removed and the upper A-arm top plate has to be flipped over. This is a direct result of an error in the Factory Five Racing Type 65 Coupe manual (revision 3E, July 2011) on pages 60 and 61 and 63 and 64.

The manual says to install the ball joint into the upper control arm to make “a left and a right.” I did this, and now must dis-assemble one of the ball joints. A new upper control arm is more than $200, so this is a costly error if I am not able to correct this.

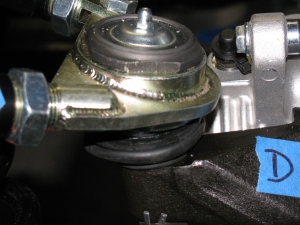

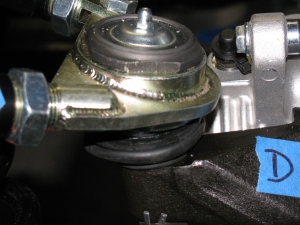

The correct orientation is shown on the driver’s side of the suspension. The passenger side is incorrect. This assembly is difficult to describe in words, so it is best shown with pictures.

Here is the driver side showing the upper control arm and the ball joint mount on the plate – see the wedge-shaped, “thicker” end at the apex of the triangular plate? This is correct.

This is the passenger side upper control arm. See the thicker wedge-shape on the opposite side of the apex? This is incorrect (wrong).

I dis-assembled most of the front suspension to get to this ball joint. However, the ball joint fits into the spindle via a tapered hole. . . meaning that some force must be applied to remove the ball joint stem from the spindle. I started by tapping – then pounding – with my plastic hammer, since I did not want to damage anything. No good. I changed to a scrap of oak and my ball-peen hammer and hit it hard for several minutes. Still no good. I got rid of the piece of wood and really slammed with the ball-peen hammer. Finally, the stem popped loose.

Of course, this created a mushroom on the ball joint stem, and it would not come out of the hole. I filed around the mushroom and finally separated the ball joint from the spindle. I should be able to file or grind the stem so the ball joint can be re-used.

Mushroom on the stem!

Removing the ball joint requires dis-assembly with 450 degrees F (since I used Permatex medium strength thread locker blue), a vise and a big wrench with lots of grip and torque.

I tried several times, but my vise just isn’t gripping the ball joint properly, it slips off. I need a bigger vise and a torch for this. My bench vise is too small.

Cutting the Dash

Since I could not remove the ball joint, I decided to move to another part of my project – cutting the dashboard in half. This is a popular modification that will increase access into the area between the dashboard and the firewall. This area will soon be stuffed with wiring and air conditioner ducting, so the dashboard had to be cut sooner or later.

I wondered how this was done, should I leave a “lip” on one of the sections so I can patch the panels together? Or do I just slice along the fold? What is the safest way to do this with my power jig saw?

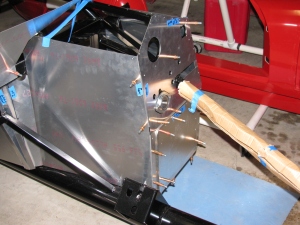

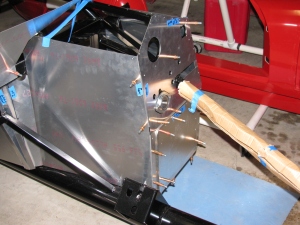

It turned out to be easier than I thought. Here are some pictures of the cutting operation . . .

I used some duct tape and a wood scrap to hold the dashboard in place for the cut. My trusty Makita power jig saw did the trick.

I will use a piece of aluminum angle stock to mend the two sections together.

I may make a new dashboard front panel, especially since the original one has several things wrong. For example, I ordered the “modern gauges” option. There is no mention that the modern gauges are smaller than the vintage gauges. The dashboard comes with cut-outs for the larger gauges, and a triangular-shaped adapter plate for the smaller gauges. Also, the steering column hole is in the wrong place, as mentioned in a previous posting. If I knew this was going to happen, I would have ordered a plain, non-drilled dashboard – so if you are planning your order – consider asking for an un-cut, un-drilled dashboard and make custom cut-outs where you want them.

Cookie Sheet Heat Shields

A few weeks ago, I found these cookie sheets in the close-out bin at the grocery store. They have nicely rolled edges and they happen to be almost the right size for the footboxes.

The amazing part about these cookie sheets is the angle at one end – it exactly matches the angle at the back of the driver-side footbox. I will mount them with 8-32 machine screws, spacers and locking nuts. I will also add a layer of insulation (Cool-It mat) between the heat shield and the footbox panels.

I am no longer sure if I want to use the Rust-Oleum BBQ paint for my firewall and other panels. I did a paint test this weekend, and the paint is quite soft, and scratches easily.

The Battery Mounting Plate

After noticing how soft that BBQ paint is, I decided to do some more paint testing. This is the battery mounting plate. It is made of steel, and it is already starting to rust. So I decided I should paint this part and the other steel items soon.

I used Rustoleum Appliance Epoxy paint for this test. This is my standard paint for radio and electronics projects. The finish is very hard and glossy, the cured surface is washable and no primer is needed. However, it is not meant for heat, the maximum temperature is 200 degrees F.

I prep the surface by scuffing the surface with 80- or 150-grit sandpaper on a random orbit sander, followed by a dish soap and water wash. I apply the paint in three or four very light fog coats and the surface becomes slightly textured. I may go with this paint, if I can find a suitable color. The last time I looked at spray paints, this appliance finish comes in white, almond and black. Too bad it does not come in silver or gray.

Roomba Battery-Ectomy – Vacuum Cleaner Battery Replacement

After almost three or four years, the battery pack in my Roomba 530 stopped taking a full charge. I re-newed the charge cycle several times, but the Roomba would run out of charge before completing a single room. So I performed a battery-ectomy on the Roomba. It needed a good cleaning inside the chassis anyway, so this was something I needed to do. You can see the debris inside the mechanisms that are impossible to clean unless you open the case. I used my shop vac to suck out the junk inside the various nooks and crannies inside the Roomba. The new battery has a larger capacity and should provide a longer running time. This will be good, since Roomba will help increase my time in the garage and other non-house cleaning activities. . . .

Here are some pictures. . .

Difficult to work in the un-heated garage on days like this. . . .

I am working on several things on the car at the same time. Whenever I get stuck or run into a problem, I move to a different part of the car to build. At some point, things will meet up and progress in a more orderly fashion, but at this stage, nothing is complete.

This Factory Five Racing Coupe project is consuming my life. Even when I am sleeping, I have dreams about the car, the building process or driving the car.

But lately I have been having nightmares about the car….

Front Suspension Re-Do

I managed to install a part on the front suspension upside down and backwards. Of course, like a lot of automotive things, in order to get to that part, a lot of other parts must be removed first. Some parts required a tremendous amount of torque to install. These are parts that should never “fall off” like anything in the front suspension and wheel mounts.

So, one of the chores I had to do was to remove the front wheel bearings and hubs. I tried to remove the mechanical lock nut with my ratchet, but it would not budge. This is a good thing, since this one nut fastens the wheel to the car. Installing these parts required several very hard whacks with my plastic hammer and several Rated R and X words and phrases. I could not help but wonder how those parts would come off if I ever needed to repair or replace them.

Reading the forums made me lose a lot of sleep, since it seems that a lot of fellow builders have had trouble with this part, too. I bought an AC-operated impact wrench and some very large (36mm) impact sockets to remove the hub nuts. As a back-up, I also bought a large 1/2-inch drive breaker bar and a piece of pipe to increase the torque if needed.

I called my friend Larry over for some assistance.

Surprisingly, the breaker bar made the hub nut come right off. Even more surprising is the condition of the spindle where the wheel and bearing mounts – it still looks brand-new and without any distortions or scratches.

After purchasing the impact wrench, Larry sent me an e-mail advising me to not use an impact wrench on the front hubs, because this may damage the wheel bearings. I took this advice, and returned the impact wrench. Good thing I did not open the box. . .

Interior (Cockpit) Aluminum Panels

After the problem with building the IFS, I decided to “dry-fit” all parts from now on. This way I can verify everything is correct – or fix things that are wrong – before tightening the parts into place.

I decided to do some more work on the interior sheet aluminum. Compared to some of the other tasks, fitting the aluminum is easy. I made some diagonal cuts along the floor to make the parts fit easier, and to prevent scratching the nearby interior panels. By cutting the single large pieces into multiple smaller pieces, they will drop into place, rather than bend and scrape into place – preserving the painted surfaces.

The seams and bend directions are hard to see in these pictures, the aluminum sheets do not provide enough contrast. I may use masking tape to show where the parts go and where the seams meet next time. As I said, this is the first attempt to fit the cockpit aluminum. Based on old Factory Five Racing forum posts, it looks like my aluminum panels have been improved somewhat. The only poorly fitting space is this big gap on the driver side, right at the corner of the transmission tunnel.

I may either trim the mounting tab behind one of the panels, or just install some sort of patch over the top. Overall, though, this Generation 2 Coupe seems to have better-fitting interior panels, so far.

Dashboard

Here is an example of something gone wrong —

Notice the odd-shaped hole for the steering column? The mounting location for the steering shaft is not straight and parallel along the ladder structure in the driver side footbox and clutch quadrant. As I examined all the parts in this area, I believe the factory did this because of an interference issue with the brake pedal. If the steering column shaft were to run parallel to the ladder structure, it would block the brake pedal actuator. Moving the mount – but not compensating for this on the dashboard panel – makes this problem look worse than it may be.

I used a nibbling tool, a round file and a sanding drum to enlarge the hole for the steering shaft.

A popular modification to the dashboard is to cut along the bend, making the one long piece dashboard into two long pieces. This enables access to the inside of the dash from the top as well as the front, and will make installing and maintaining dash components such as gauges, air conditioner and plumbing much easier. I will make this cut at the next build session.

I just have to figure out a way to disguise the big and ugly hole in the dashboard. . .

The Racing Seats

I placed the Kirkey high-back racing seats to see how it fits, and although the steering wheel is a bit toward the passenger side, I think it will be all right.

Clutch Quadrant and Pedal Box

Many Coupe builders owe a lot to a guy named Chris, who has documented his Type 65 Coupe build experience with lots of pictures. (I added a link to his flickr photostream in the Automotive Links section.) The Factory Five Racing assembly manual left an entire section out for us Complete Kit builders. There are no instructions for the Wilwood pedal box and clutch quadrant assembly. Thanks Chris for sharing your images!

Anyway – here are some pictures of my Wilwood pedal box and clutch quadrant. I do not have too many fitment issues here, except for the mounting points to the 3/4-inch tubes – I will have to wedge the mounts at the firewall in order to securely mount the pedal box to the ladder structure. I painted my footbox mounting plate with silver Rust-Oleum BBQ paint. I wanted to do a test to see how the color came out and how durable the finish is. I like the color, it is much better than the raw steel and hopefully will prevent any rust from forming inside the car.

A Roadster Driver Visits

Rick, a neighbor and Roadster owner, stopped by for a visit. Here are some pictures of his very nice car. Rick did the paint job by himself in his garage – I am very impressed with the way the finish came out – take a look!